Electrical Calibration

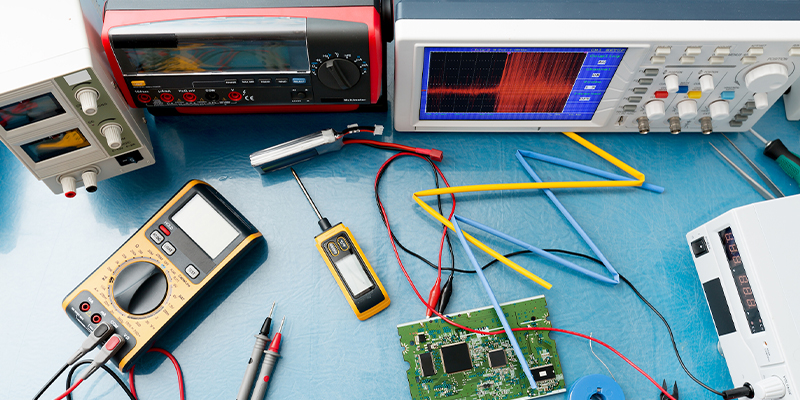

At VIPL Group, we provide accurate and reliable electrical calibration services to ensure that all electrical measuring instruments deliver precise and consistent readings.

In industrial, manufacturing, and testing environments, measurement errors in electrical parameters can lead to equipment faults, quality issues, and safety risks.

Our electrical calibration services help organisations maintain measurement accuracy, prevent failures, and meet essential quality and compliance standards.

What Is Electrical Calibration?

Electrical calibration is the process of verifying and adjusting instruments that measure electrical values such as voltage, current, resistance, power, frequency, and continuity.

Over time, electrical devices may drift due to usage, thermal stress, or environmental conditions. VIPL Group uses traceable reference standards and certified procedures to ensure every instrument performs accurately and reliably.

Why Electrical Calibration Matters

- Ensures Measurement Accuracy: Precise electrical measurements are critical for production, testing, and troubleshooting.

- Prevents Equipment Failures: Calibrated instruments reduce the risk of overloads, incorrect readings, and electrical faults.

- Supports Compliance: Industries must follow ISO, NABL, and safety guidelines. Proper calibration keeps your facility audit-ready.

- Enhances Safety: Accurate electrical values help maintain safe operating conditions for workers and machinery.

- Reduces Downtime & Repair Costs: Well-calibrated instruments help avoid unnecessary breakdowns and prevent defective batches.

Electrical Calibration Services by VIPL Group

We calibrate a wide range of electrical measuring instruments used in industries, laboratories, and service facilities, including:

Voltage & Current Measuring Instruments

- Digital multimeters (DMM)

- Clamp meters

- Milliamp/amp sources

- Voltage sources & simulators

Resistance & Continuity Equipment

- Insulation resistance testers

- Earth resistance testers

- Meggers

- Ohm meters

Power & Frequency Instruments

- Power analyzers

- Watt meters

- Frequency counters

- Function generators

Process & Industrial Electrical Instruments

- Panel meters

- Process indicators

- Transmitters

- Recorders & controllers

Why Choose VIPL Group?

- Calibration traceable to national & international standards

- Skilled technicians and certified calibration procedures

- High-accuracy reference equipment and advanced testing systems

- On-site and in-lab calibration support

- Fast turnaround with minimal operational interruption

- Comprehensive calibration certificates for audits

- Custom schedules for industrial electrical equipment

Our Calibration Process

- Inspection & Pre-Testing: Condition and initial performance check.

- Reference Comparison: Measurements compared against traceable standards.

- Adjustment & Fine-Tuning: Corrections made for accurate performance.

- Final Verification: Precision testing after adjustments.

- Certification:

A detailed certificate is issued with:

- Test results

- Uncertainty values

- Traceability information

- Technician details

- Recommended next calibration date