Torque Calibration

At VIPL Group, we provide precise and reliable torque calibration services to ensure that torque-measuring and torque-applying tools deliver accurate, consistent, and repeatable performance.

In industrial, manufacturing, automotive, and assembly environments, even a slight torque variation can lead to product defects, equipment damage, or safety hazards.

Our calibration solutions help organizations maintain measurement accuracy, improve assembly quality, and meet national and international calibration standards.

What Is Torque Calibration?

Torque calibration is the process of verifying and adjusting torque tools to ensure that they apply or measure torque within the correct and defined limits.

With regular use, mechanical wear, temperature changes, and operational stress can cause torque tools to drift from their intended accuracy. VIPL Group uses certified torque calibration equipment and traceable reference standards to guarantee accuracy and compliance.

Why Torque Calibration Matters

- Ensures Product Quality & Assembly AccuracyCorrect torque ensures proper fastening, preventing loose joints or over-tightening issues.

- Enhances Equipment Safety Accurate torque tools reduce the risk of equipment failure, hazards, and production breakdowns.

- Supports Industry Compliance Ensures adherence to ISO, NABL, automotive, aerospace, and manufacturing standards.

- Reduces Production Errors & Rework Properly calibrated torque tools help avoid costly mistakes during assembly and testing.

- Extends Tool LifespanRoutine calibration helps maintain tool performance and minimizes unexpected faults.

Torque Calibration Services by VIPL Group

We provide complete calibration services for a wide range of torque-measuring and torque-controlling instruments.

Torque Measuring Instruments

- Torque wrenches

- Digital torque testers

- Dial-type torque wrenches

- Click-type torque wrenches

Torque Applying Tools

- Pneumatic torque tools

- Electric torque tools

- Screwdrivers (manual & powered)

- Nut runners

Specialized Torque Devices

- Torque sensors & transducers

- Torque multipliers

- Automated torque systems

Why Choose VIPL Group for Torque Calibration?

- Calibration traceable to national & international standards

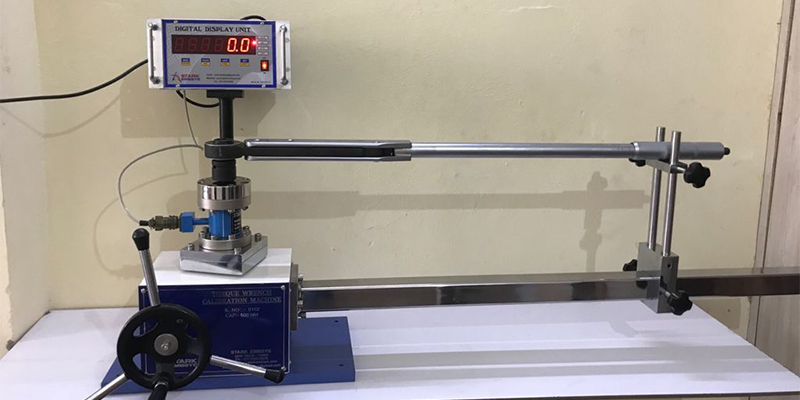

- Precision torque calibration benches and master equipment

- Skilled engineers with industrial and automotive experience

- On-site and in-lab calibration support

- Quick turnaround with minimal equipment downtime

- Detailed calibration certificates with full traceability

- Customized calibration schedules for plants and QC labs

VIPL Group ensures that every torque tool is tested, adjusted, and certified for optimal accuracy and reliability.

Our Calibration Process

- Inspection & Pre-Check: Tools are evaluated for condition, functionality, and mechanical issues.

- Measurement Comparison: Torque values are compared against certified reference standards.

- Adjustment & Fine-Tuning: Deviations are corrected to restore accurate torque output.

- Final Verification: Post-adjustment testing ensures consistency across the torque range.

- Calibration Certificate:

Each tool receives a certificate that includes:

- measured torque values

- accuracy deviations

- traceability

- uncertainty

- technician and lab details

- recommended next calibration cycle.

FAQs

Generally every 6–12 months, depending on usage, application, and industry requirements.

Yes, VIPL Group offers both on-site and in-lab calibration services.

We handle a wide range of torque tools from low-torque screwdrivers to high-torque industrial equipment.

Yes, all certificates are traceable to national and international standards.

We deliver certified, accurate, and reliable calibration supported by advanced equipment, experienced engineers, and detailed documentation.