Gauges Calibration

At VIPL Group, we provide accurate and traceable gauge calibration services to ensure all your measuring gauges perform with precision and reliability. In manufacturing, machining, automotive, aerospace, and QC labs,

even the smallest deviation in gauge readings can lead to product defects, tolerance errors, and quality failures.

Our calibration solutions help industries maintain measurement accuracy, meet compliance standards, and ensure consistent production quality.

What Is Gauge Calibration?

Gauge calibration involves comparing a gauge’s readings against certified reference standards and adjusting it (if required) to restore accuracy. Over time, gauges can drift due to frequent usage, friction, environmental changes, or mechanical wear.

VIPL Group uses master equipment, controlled environments, and standardised procedures to ensure every gauge delivers repeatable and accurate measurements.

Why Gauge Calibration Is Essential

- Ensures Dimensional Accuracy: Proper calibration ensures that critical dimensions meet required tolerances and product specifications.

- Reduces Production Errors: Misaligned gauges lead to rework, scrap, and assembly issues. Calibration helps detect and correct deviations early.

- Maintains ISO & Quality Compliance: Industries following ISO/IEC 17025, NABL, or internal QA guidelines require periodic gauge calibration with proper documentation.

- Improves Tool & Equipment Reliability: Regular verification enhances gauge life and reduces downtime caused by inaccurate readings.

- Supports Consistent Product Quality: Stable, accurate gauges help maintain uniformity and standardization in manufacturing processes.

Gauge Calibration Services by VIPL Group

We calibrate a wide range of dimensional gauges for various industries:

Dimensional Gauges

- Vernier calipers

- Micrometers (inside, outside, depth)

- Height gauges

- Bore gauges

- Dial indicators

- Feelers & slip gauges

- Thread gauges (plug, ring, snap)

- Limit gauges (GO/NO-GO)

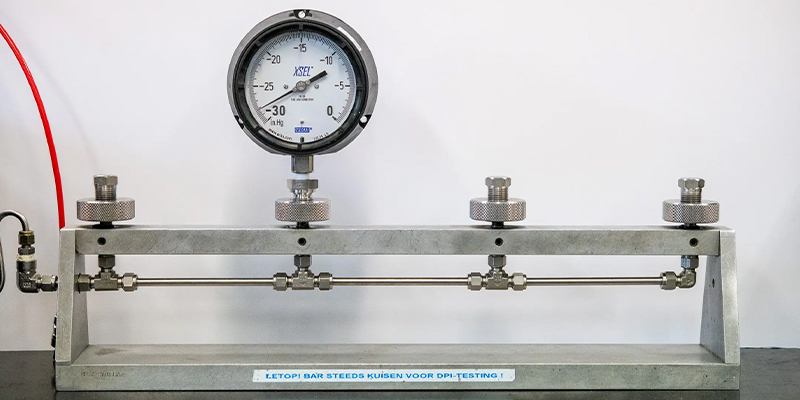

Mechanical Gauges

- Pressure gauges

- Vacuum gauges

- Differential gauges

Precision & Workshop Gauges

- Dial test indicators

- Thickness gauges

- Radius gauges

- Taper gauges

- Profile projectors (as applicable)

All calibrations are performed under controlled lab conditions using traceable master standards.

Why Choose VIPL Group for Gauge Calibration?

- Calibration traceable to national & international standards

- Advanced metrology lab with precision-grade reference masters

- Skilled engineers and validated calibration procedures

- On-site and off-site calibration support

- Fast turnaround with minimal operational disruption

- Detailed calibration certificates required for audits

- Custom calibration schedules for industries

VIPL Group ensures every gauge is tested thoroughly, corrected when needed, and certified with complete accuracy assurance.

Our Calibration Process

Pre-Inspection: Gauge is visually checked for wear, damage, or mechanical faults.

Measurement Comparison: Readings are compared with master standards to check errors.

Adjustment & Fine-Tuning: If discrepancies are identified, adjustments are performed wherever possible.

Final Accuracy Verification: Rechecking is done to ensure compliance with tolerance limits.

Certificate Issuance: A calibration certificate is provided, including:- Actual readings

- Errors noted

- Uncertainty values

- Traceability details

- Technician signature

- Next due date

FAQs

Most industries follow a 6–12 month cycle depending on usage, environment, and tolerance requirements.

Yes, VIPL Group provides both in-lab and on-site calibration for convenience.

Yes, all certificates are fully traceable to national and international standards.

We calibrate dimensional, mechanical, pressure, thread, and precision gauges across various sectors.

We deliver accurate, reliable, and certified gauge calibration using advanced equipment and trained technicians.